If you've pulled up to our Toyota dealership recently, you were probably understandably shocked by the lack of new inventory we have kicking around. It's not normal for a high-volume dealership like ours to have a lacking supply of the new Toyota Camry or Tacoma. So, what's the big deal? Well, that's a complicated one to answer.

The automotive industry, like almost every other one out there, has been experiencing supply chain issues brought on by several factors going on in the world right now. If you're one of the many people who's concerned about the lack of supply and choices when it comes to purchasing a new Toyota, you'll want to read this. Toyota of Orlando is diving into the global supply chain issues plaguing the automotive industry right now and what you should do in response.

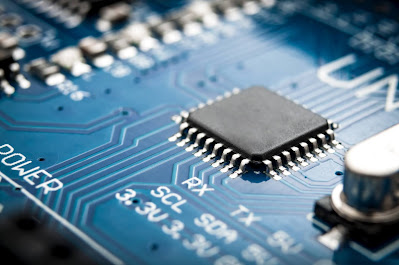

When the Chips are Down, What Do You Do?

It's an understatement to say that the coronavirus pandemic has upended quite a lot and exposed the weaknesses in our global supply chains. Shipping goods and various items worldwide requires precise timing and even one ship stuck in, say, the Suez Canal (looking at you, Ever Given), can delay the production and sale of products on a massive scale. If you've been trying to get your hands on a PS5 or Xbox Series X/S lately you know what we're talking about.

With Orlando supply chains heavily affected by the ongoing global pandemic, harsh regional weather conditions, and more, Toyota vehicles are in short supply. The parts affected specifically include semiconductor "chips" which have hampered the production of many Toyota models and other

electronic-based devices. Let's dive into what this part is used for, specifically, and what that means for you when you're searching for a new Orlando Toyota Tacoma.

Briefly on Semiconductors

Semiconductors, or chips in this case, are small devices used as part of an electronic system to distribute power to various devices throughout the vehicle. Essentially, you need them if you want to use anything electronic in your Orlando Toyota car. They allow for the use of important features like the battery, safety systems, infotainment, lighting, and so on. They're typically made of germanium and silicon and are used in just about every modern vehicle out there on the road.

Depending on the extent to which your

vehicle uses electricity, the semiconductor can be larger or smaller. A typical internal combustion engine (ICE) uses one to, namely, distribute and manage power from the battery to operate other accessories. In highly electrified vehicles like a hybrid or

battery electric vehicle (BEV), semiconductors control larger areas of the engine compartment and power far more features.

So, what does this all mean for supply chains and the amount of

vehicles being produced going forward? It means that the automotive industry, and many other ones that deal in electronic goods, will likely be suffering supply chain issues for a lengthy period of time. Toyota itself has had to shutter various assembly plants in the U.S. due to the gross shortage and it could take months or maybe even a year before the global supply chain of chips returns to normal. Even then, it could take a while before production catches back up to pre-pandemic levels.

Still looking for a new ride? Toyota of Orlando is here to help! Visit the dealership at 3575 Vineland Road and shop with us today.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.